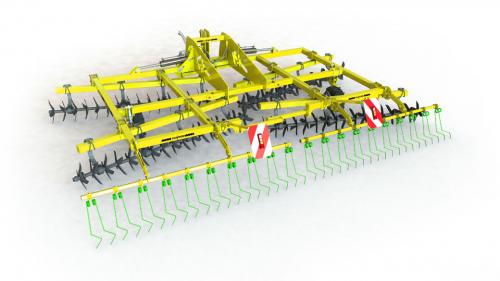

Claydon Hybrid M – Mounted Drills

Incredibly versatile, flexible and simple. Drill direct into stubble – min till – or plough.

Description

Incredibly versatile, flexible and simple. Drill direct into stubble – min till – or plough. Over 16 years’ development experience.

The leading tine busts out compaction, puts air in the soil and creates drainage and tilth for the seeding zone. The seeding tine then creates more tilth and places the seed under the tilth at your chosen depth above the drainage channel.

- High clearance

- Simple to set up, easy to use, very low maintenance

Super-Efficient Strip Till

Claydon Hybrid Drills deliver on the promise of super-efficient strip tillage. Incorporating the leading Claydon in-line tine design, all models benefit from a range of stand-out features to make this a truly versatile tool for low cost establishment:

- Simple, strong, lightweight design.

- HUGE trash clearance.

- Low horsepower, low fuel usage.

- Low running costs: minimal wearing and moving parts.

- Long-life tungsten carbide leading tines.

- Quick, easy servicing – change wearing metal in minutes.

- Highly manoeuvrable.

- Exact seed placement – wheels run on undisturbed ground.

- Constant seed depth from stiff spring steel seeding tines.

- No capping – wheels run between the seeded rows.

- Levels fields, follows contours with soil grading chassis design.

- Easy calibration, intuitive controls.

Integrated Fertiliser Options

For the Claydon Hybrid mounted machines, fertiliser technology is offered as a complete unit in the 3m fertiliser drill. Hoppers can be fitted to any mounted Hybrid drill. Granular or liquid fertiliser hoppers can be fitted to the front. A microfert tank can be fitted to the rear.

Additional information

| condition | |

|---|---|

| make |

Video

Claydon Direct Seed Drills

Claydon Drills are the most renowned direct strip till seeding system in Europe, giving sustainable high yield results year on year with huge environmental benefits. Their seed drills can be used direct into stubble or cultivated soils giving huge time and cost savings when used as a direct drill.

The leading tine can be adjusted to a depth of between 0 for low disturbance and 15cm (6 inches) for deep rooting crops like OSR. The second tine can be adjusted via the depth wheels to put the seed in as shallow or deep as necessary.

- Centrally mounted depth wheels give very accurate seed placement as they run on undisturbed soil between the rows and do not run over or cap the seeded area.

- Stone protected leading tines break through the ground lifting and aerating it whilst creating a drainage tract and space for the roots to grow deep and strong with ease.

- Solid sprung seeding tines keep a highly accurate and constant seed depth, flowing through the soil lifted by the leading tines and cultivating it whilst only moving for a large stone.

- Levelling boards and tines leave a superbly level finish covering the seedlings in a perfect soil plant pot with drainage and space for root development.

- Fertiliser can be placed below the seed (front tine) or above the seed (rear tine) with the standard tine set up. With the twin tine option, fertiliser can be placed below the seed only.